Tablet coating is solitary of the oldest pharmaceutical process still is endurance. Coating is a sequence by which an essentially dry, exterior layer of coating substance is practical to the external of an amount form in demand to confer definite reimbursement over uncoated diversity. It involves demand of a sugar or polymeric coat on the capsule. The recompense of tablet coating are odour mask, chemical defence flavour mask, physical and, protect the medicine in the abdomen, and to direct its let go profile. Coating may be practical to a widespread diversity of spoken solid amount form, such as element, tablet, crystals, granule, pellets and powder. When coating sonata is practical to a batch of tablets in a coating pan, the pill surface becomes covered with a tawdry polymeric film. There are numerous techniques for tablet coating such as enteric coating sugar coating, and film coating. The disadvantage of the older techniques of coating has been conquering with the recent progression in coating technologies. In this technology coating resources are in a straight line applied on the exterior of the tablet with no the use of any solvent. ICH guidelines also prefer the evading of organic solvents in pharmaceutical dosage formulations allowing for produce safety profile. This reconsider discuss the basic concept of tablet coating, the current advancement made, the difficulty faced throughout the development, their solution and coating assessment.

Introduction

Tablet coating, tablets, Pills and candies with organic film can be described as a procedure of be relevant an edible paint on the surface of a pharmaceutical dosage form to achieve specific benefits. This is an additional process in tabulating which cause an increase in the cost of tablet manufacture. Coating can be functional to quite a few kinds of solid dosage forms like crystals, drug, pills, tablets, pellets, etc. When a coating solution is functional to a consignment of tablets in a coating pan, the surface of the remedy get covered with a tacky polymeric film. The tablets are then authorized to dry and the film ultimately forms a non-sticky dry exterior. The coating system involves parameters such as the nozzle spacing, drop size and spray pattern, (in adding together to numerous other non-spray interrelated parameter) which must all be accurately forced in order to make sure standardized allocation of the coating substance

Coating process

It is mostly attractive that the coating should be standardized and has to not crack less than stress. Consequently, a variety of technique was intended for the request of the coating on the tablet exterior. Normally, the tablet coating solution is sprayed onto the uncoated tablets as the tablets are being disturbed in a pan, fluid bed, etc. As the explanation is being functional, a thin film is produced which sticks to each tablet. The fluid division of the coating solution is then evaporating by transitory air over the exterior of the reducing pans. The coating may be shaped moreover by a single request or may be industrial in layers from side to side the use of numerous spraying cycles. Gyratory coating pans are frequently used in the pharmaceutical manufacturing.

Sugar coating / Sugar Film

Tablet coating urbanized in the beginning from the use of sugar to masquerade the taste and supply an attractive exterior to at the core. The method of tablet coating consists of quite a few steps, which are described below:

Sealing

A seal coat is functional over the tablet to avoid dampness penetration into the tablet core. Shellac was before used as a sealant. But due to polymerization problems, it was substitute by zein (a corn protein derivative).

Sub coating

This step is complete to round the boundaries and enlarge the tablet mass.

Syrup Coating

The imperfection in tablet surface is enclosed up and the prearranged size is achieved. This step requires the utmost ability.

Colouring

Give the capsule its final colour.

Polishing

Powdered wax (beeswax or carnauba) is functional to provide a desired sheen.

Film coating

As the sugar coating procedure is very time strong and is needy on the skills of the coating operator, this system has been replace by film coating technology. The procedure involves spraying of a explanation of plasticizer, pigment and polymer, onto a gyratory tablet bed to form a thin, standardized film on the tablet exterior. The option of polymer mainly depends on the essential site of drug release x or on the necessary release rate.

Organic film coating

At present, the mainly frequent machinery for coating solid dosage forms is the liquid coating technology. In fluid coating, a mixture of polymers, pigments and recipients is dissolved in an organic solvent or water to form a solution, or dispersed in water to form a scattering, and then sprayed onto the quantity forms in a pan coater and dehydrated by incessantly as long as heat, characteristically by means of hot air, until a dry coating film is twisted. Organic solvent base coating provide a multiplicity of helpful polymer alternative, as mainly of the polymers are soluble in the extensive range of organic solvents. However, there are convinced disadvantage like they are combustible, toxic, and valuable and own environmental issues. ICH strategy also prefers the avoidance of organic solvents in pharmaceutical quantity formulations in view of products safety shape. So, Pharmaceutical industries are now paying much interest in early formulations with aqueous film coating.

Aqueous film finish / Aqueous Coating

All above nuisance with organic solvents resulted in change to use of irrigate as the preferred coating solvent. Aqueous-based coatings have been more and more used compare with organic base coatings. The exchange from organic solvent based coating to aqueous based coating makes the coating development more efficient, though originally it can need a little investment to improve the coating ability.

The necessitate of this up-gradation arise due to of advanced drying aptitude. This imply that one would necessitate 4 times more energy as compare to organic solvent

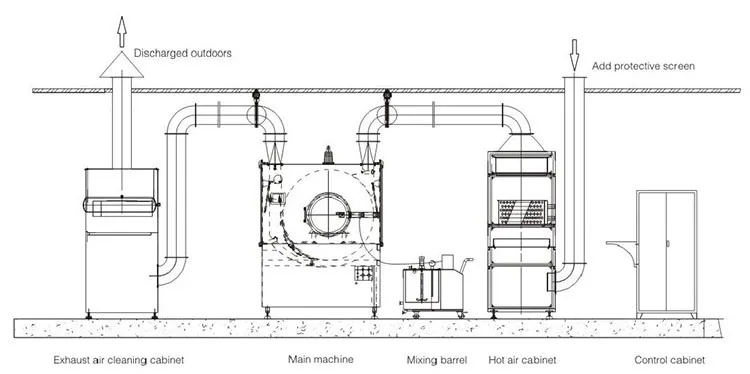

Automatic Tablet Coating Machine – Tablet Coater

Features of Senieer Tablet Coating Machine:

- 2 Bar S.S. 316/304 Construction: tight dimensional tolerance, GMP compliance, and absence of fractures or fissures.

- Application of Coatings Across the Board: Water Solvent. The coating procedure is optimized by the sugar spray gun setup.

- Outstanding Process: Air Flow A wholly enclosed, extremely effective airflow system is used in the innovative perforated pan design to ensure maximum drying uniformity and minimal process air consumption.

- Quick and Simple Cleaning: C.I.P System

- Material Handling System: automated system for unloading.

- Spray System for Precise Solutions: Imported spray guns and a removable spray gun bar with a solution tank and a highly precise peristaltic pump.

- Control of automated processes: PLC control system for thorough monitoring, recording, and managing all important processes parameters

- Protection of the environment and safety: The auto-coating machine is equipped with a specific technology to stop all powders and fugitive coating material, neutralize solvent fumes, operate completely cleanly, and prevent environmental contamination.

SHREE BHAGWATI tablet coating machine function

- Depending on the kind of tablet and the desired coating, choose the appropriate coating materials.

- The tablets are then placed in a drum and rotated in an orbital pattern, with the streamlined plates controlling the majority of the operations.

- The nozzle sprays a coating solution that is controlled by an automated control system while the drum rotates.

- The method guarantees that the coating on the tablets is applied accurately and evenly.

- The machine pushes hot air into the drum as the spraying continues, resulting in a fast application of the solution.

- It maintains the same temperature on its own to keep the drug’s composition in excellent shape.

- When the required coating is achieved, the tablets are moved to the drying area, where air is blown over them.

- This is how the tablet coating machine works before the packing process, with the volume of air being controlled to ensure no interaction with the pills.

Process of tablet coating

There are 3 main processes of tablet coating here we can say film coating, enteric coating and sugar coating.

Film coating: A thin layer of a film-forming polymeric is deposited onto a product substrate in the process of film coating. The procedure can be carried out with standard panning equipment, but modern equipment is more advanced in order to provide effective drying, a high level of automation, and quick coating.

Film coating is a typical process in the production of tablets and can be used to enhance the product’s appearance, organoleptic qualities, or swallowing convenience. Functional film coats can also be utilized to adjust or postpone drug release as part of the product’s stabilization strategy.

Sugar coating: In quick release applications, sugar coating is used to hide the undesirable flavor and odor of some medications or to enhance the product’s visual characteristics. It is important to realize that the coating procedure may affect how quickly a medicine dissolves while also delaying the overall disintegration of the tablet.

The sugar coating serves as a barrier to external pollutants and safeguards the medication inside the tablet, among other functions.

Enteric coating: A polymer known as enteric coating is put on oral medications. It acts as a barrier to stop medications from being dissolved or degraded by the stomach’s gastric acids after you swallow them. Many medications would dissolve quickly in stomach acids without complete enteric protection. For medications like insulin that rapidly disintegrate in the stomach, enteric coating is a helpful delivery method because it stops the drug from being released in the stomach’s acidic environment before it reaches the intestine.

Types of Tablet Coating Machines :

There are three types of Tablet Coaters:

Standard coating pan: It consists of a circular metal with a diameter of 6-8 inches. It is slightly tilted 45 degrees to the benchtop and has an electric motor that rotates a metal pan horizontally to its axis. Improper balancing of inlet and exhaust air is a shortcoming experienced, which can be collected by adding components such as immersion tube system, immersion sword, baffled pan, and diffuser.

Perforated coating plan: Consists of either a fully or partially perforated drum and features a horizontal axis rotation of the drum. It displays an efficient drying system and a high tablet coating machine capacity.

Fluidized bed coater: It works by turning material particles for coating into a fluid followed by spraying.

The various types have a ground in the medical industry for pharmaceutical drug manufacturing and the cosmetic industry, where they add color on their products to make them attractive for sales increase.

Recommended Operations for minimizing coating defects:

Spray rate: A low spray rate results in insufficient wetting, creating a brittle coat while a high spray rate over wets the tablets making them too sticky. Ensure the right spray rate before you begin the operations.

Air capacity: Air aids in drying the coated tablet, ensure sufficient air supply to prevent the occurrence of defects.

Coating composition: The operator must caution the proper mixing of materials to prevent defects such as a blockage.

Rotation speed should not exceed optimum levels, and to achieve proper equipment efficiency, ensure all other components are operating at optimum levels under appropriate regulation of the processes.

Get yours instantly at an affordable tablet coating machine price to achieve your desired coatings. You can request an instant quote for tablet coating machine by clicking contact below and posting your requirement.

Tablet Coating Pan, Pan Coating Machine, coating machine in pharmaceutical industry