Shree Bhagwati make the wide product range of mass mixer has been well-designed to facilitate methodical mixing of dry or moist supplies and is particularly appropriate for tablet granulation. The commanding geared drive and strong Paddle mixing make Bhagwati Mixer perfect for selling with tricky or tacky element. This is one haste Mixer but two hustle mechanism obtainable on command. The Mass Mixer mechanism is fundamentally combination and congregation in which the mixing stirrer is in horizontal position in the container & has a solitary haste, straightforward rotation. The agitator rotate approximately itself at a extremely sluggish speed within the bowl and in that way achieve close mixing of Confectionaries Materials, Chemicals, Tablet Granulation dry or wet materials of, Powder, Food &. Because of a particular intend characteristic of mechanism & agitator, the mass mixer can be combining the tacky materials & also homogeneously and confidentially combine the equipment which is to be hard to combine.

Construction

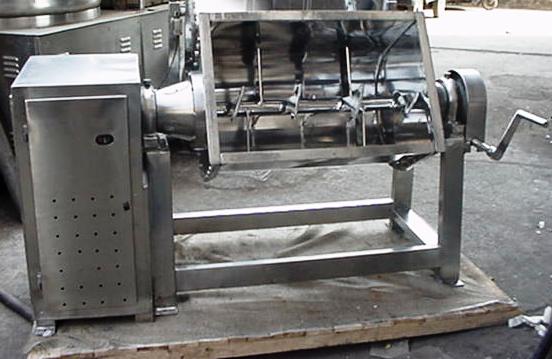

The Mixer consists of mixing drum absolute in itself. It contains combination drum body. Combination paddle and sealing pact the drum rests on unbending SS fabricated body transport Motor, tilting arrangement, Starter, and Gear box. The drive of combination paddle is from side to side appropriate oil filled worm gear unit which in revolve get drive through V belts from an appropriate T.E.F.C. motor. The blades of the paddle are so orderly that methodical integration is obtained. All parts which are in straight contact with the substance to be varied are of S.S. or unbiased material. The main paddle runs in journal and support by thrust bearings of ample size to transmit rigid and thrust load. The complete drum of mixer makes effortlessness of cleaning. The rotor is so intended that it can be removed; by remove the major shaft with no a large amount problem. Variety of Mass Mixer models to suit operational quantity 50,100 & 200 Kgs. At bulk density of 0.50 gms/cc. All contact parts of mass Mixer Machine are made out of S.S.316 superiority material. All non contact parts in the mass mixer (general arrangement) are made out of with SS316 or chrome plated (If customer request) or made out of SS304 in GMP Model. Contact parts are refined to the mirror finished and non contact parts are elegant to the matt finished in GMP Model. All protection guards & covers made out of SS316 material in GMP model. All touching parts are covered with protection guards.

Plastic Grime Cover

The material under combination process can be it seems that seen from the Plastic grime Cover of the storage space place at all period and it, person hinged and asset allows explanation to be additional from side to side with no complexity at the same time as the blender is in movement.

Safety

The plastic grime cover is so interconnect that on chance the wrap the motor routinely stops. The interlock agreement is convinced to wait away beginning the accident as the method will not commence if not and pending container is completely closed. This is of greatest significance in a mechanism like this which has rotating blades.

Sloping mechanism

The Tilting Device is providing to effortlessness the receiving of the matter. Tilting is pretentious by resources of a hand wheel on the body, the fine particles or granule being tip into a container which can be located at simplicity.

Sealing planning

particularly intended self-adjusting sealing planning of exceptional intend is provide to warrant so as to no black element enters interested in the combination drum. On the other hand, little powder from in the interior could come out a little after a long use which suggests maintenance and readjusting of pressure spring.

Mixing Mechanism:

Paddle type blades weld to the most important shaft make available for well-organized mixing of thick heavy substance. PTFE gland machinery provide at shaft ends prevent entrance of external powder into the trough and prevents leakage.

Charging:

From the top charge can be completed from side to side a hinge able top, hopper or Nozzle can be providing for added spraying of additives.

Discharge:

By base discharge slip Iris or Butterfly valve of appropriate diameter, for synchronized release.

Drive:

Consisting of appropriate H.P. TEFC 3 phase ac 415v / 50 cycles motor joined to appropriate worm gear, with heavy shafts mount on appropriate Plummer chunk.

Mounting:

mount on appropriate ISMC segment Stand, with shielding covers for belts and combination.

Moc:

All contact parts in S.S. construction. Whole component with S.S. cover and all surface refined to mirror dull finish. MS parts dull tinted to even finish.

Mass mixer is a specially designed pharmaceutical machinery, that is used to blend both wet as well as dry material and it is best suitable for tablet granulation. Mass Mixers are perfect for mixing of pharmaceutical chemicals, powders, confectioneries, food etc.

Mass Mixer , mass mixer machine

Plastic Dust Cover

Safety

Sealing Arrangement

Lubrication

Provision is made for lubricating all moving parts and specially designed to prevent oil coming in contact with the powder.

Mass Mixer Machine ass Mixers are perfect for mixing of pharmaceutical chemicals, powders, confectioneries, food

Technical Specification :

| Models | MM-50 | MM-100 | MM-150 | MM-200 | |||||

| Gross capacity | 110 ltrs. | 220 ltrs. | 330 ltrs. | 440 ltrs. | |||||

| Working capacity | 88 ltrs. | 156 ltrs. | 234 ltrs. | 309 ltrs. | |||||

| Electricals | 3 HP/ 3Ph. | 5 HP/3 PH. | 7.5 HP/3 PH. | 7.5/3HP35 | |||||

| RPM | 35 | 30 | 30 | 30 | |||||

| Capacity | 50-200 kg |

| Brand | SHREE BHAGWATI |

| Model | MM |

| Design Type | Standard |

| Max. Mixing Mass | 50,100,150,200,300 kgs |

| Drive Motor Power | 2 hp to 10 hp |

| Weight | 300 to 500 kg |

| Minimum Order Quantity | 1 Unit |