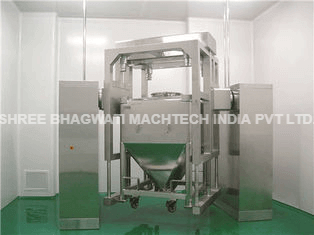

Tumbler blenders or IBC Container tumblers are used mainly for amalgamation of dry fine particles for tablet and capsule creator, which make possible enhanced pour for medication and capsule. This is a blocked controlled, completely stain free lonely step convey constitution. It can be management more than one amount of IBC container tumblers.

In granulation region the dry granule goes from side to side to the IBC container for amalgamation from side to side a stain free connection and the similar IBC container is laden in surplus of the mixer for blending. The IBC bin protected in the motionless frame in 15° after that lifted by hydraulic structure to increasing for moving elevation following that the IBC bin rotates for blending. This identical IBC container after mixture rises above the tablet press for reception in to the tablet press hoppers.

The Cage Blenders system is a fourth originator arrangement intended as an essential cycle arrangement from formulation to operation. It involves addition and batch recognition of the creation throughout in-between steps within the same hermetically preserved container. This organization allows that the G.M.P. is follow as intimately as probable (no cross stain, no location of the surroundings)

(I) S.S.BINS

The bins are mound able single over the previous and shall have whole constancy.

The bins are able to be lifted stack and elated by Fork Lift Trucks.

The charge opening with wrap is providing on top with rapid aperture & concluding planning.

The bins are extremely refined from interior & exterior.

(II) The Cage

The Drum Blender is fabricated with SS structure with 2 shafts mount on Plummer block it is joined to the drive consisting of motor and gear box of necessary dimension. Flanked by motor and gear box a fluid combination to obtain care of preliminary torque is providing. Manual inching engagements to transport the cage in arrangement is provide.

The intend of the cage and the following arrangement is such that the bins can be loaded & separate from the cage by income of fork lift trucks thereby eliminate physical hand.

The stipulation of locking agreement for the door & clamping of bins tightly is totally tool pooof. An appropriate lattice approximately the cage is provided with an admission point for the fork list. A bound switch is included in the electrical route to put off the purpose of the cage when the door is unwrapping.

(III) MS Trolleys

The bottom frame shall consist of MS Angle iron by means of a cover top.

It shall have 2 nos. permanent types & 2 nos. revolve type castor wheels.

A permanent grip made out of MS Pipes shall be provided for easy movement of trolleys.

It shall be given 2 coats of red oxide basic coverage and 2 coats of enamel dye of appropriate colour.

Design Structure:

- The Container Tumbler Blender is intended by cGMP - Current Good Manufacturing Practices compliance

- All contact parts are SS 316 and non contact parts are SS 304.

- IBC Bin Tumbler Blender for perfect dry vanquisher for lubrication of granule and homogenization addition and programme of the fabric to more series.

- Indistinguishable distorted ability IBC Bin mixer can be worn on similar instrument use for mixing.

- This is a stopped up and protected agreement whereby an introverted movement transmit the substance from Container of the Conta blender is transfer to the capsule press hopper.

- In granulation area the dry granule go from side to side to the container for amalgamation throughout a grime free bond and the identical container is laden over to the blender for amalgamation

- Also an extra benefit is flexibility of this arrangement to grip more than one dimension of bunkers or containers so indulgence of distorted sizes of produce batches in solitary equipment.

- Enclosed inflexible drive with reduction mechanism box and motor in the instrument pillar agreement.

- Hydraulic power pack preparation for lifting of manufactured goods bin for addition.

- A suitable reel approximately the cage with one entry point for the bin on detachable trolley

- The charge hole with wrap is provide on top with rapid opening and concluding research with grime proof joint for particle free convey.

- IBC Bin mixer have exonerate with butterfly control device and trolley for easy mobility.

- inspiring controls panel with series instance.

SPECIAL THINGS ABOUT SHREE BHAGWATI:

- We are giving the World Wide Installations

- Satisfaction Guaranteed for Prompt Technical Support.

- Fast Delivery for anywhere

What is Bin Blender or IBC Blender?

Bin Blender or Formula Blender: Pharma – FDA , GMP

Bin blender is used in many different industries to perform different functions.

Whether you are in a pharmaceutical, health product, food processing, cosmetic, chemical processing, drinks or beverage industries, you know the importance of bin blender when it comes to mixing products.

The blending system is usually used to achieve a smooth mixture which will go a long way in guaranteeing the quality of the final product.

Shree Bhagwati Pharmaceutical bin blender mix dry granules, powders or granules, and powders.

Bin Blender is also called powder or Formula blender or Pharmaceutical powder blender.

Are you planning to buy Pharmaceutical Bin Blenders?

This guide will be of great help to you in your search. From laboratory bin blender to bin blender scale up production.

Cage Blender, Conta Blender, Bin Blender, IBC Blender, Pharmaceutical Blender

cGMP Compliant Blending Bins

The blending system fully complies with the cGMP conditions for the production of pharmaceutical products. From a laboratory IBC Bin Blender or formula blender up to a drum, container or customize blender.

Fully Automated Bin Blenders for Pharmaceuticals

Fully automated, validated blending process with a tumbling movement: By doing without IBC Blender blades, mixers, etc., a blending process could be developed that protects the product and is 100% compliant with hygiene standards. This involves less cleaning effort and thus contributes to savings in time and costs.

Blending Bin: Uses

Integrated handling functions for lifting, slewing, or tilting all kinds of bins: For optimal connection of upstream and downstream production steps. e.g filling or discharging

Space-saving single column principle can be implemented as an in front of the wall or behind the wall construction: To make your system architecture as flexible as possible.

Consistently simple and ergonomic operation: For safe and error-free-work.