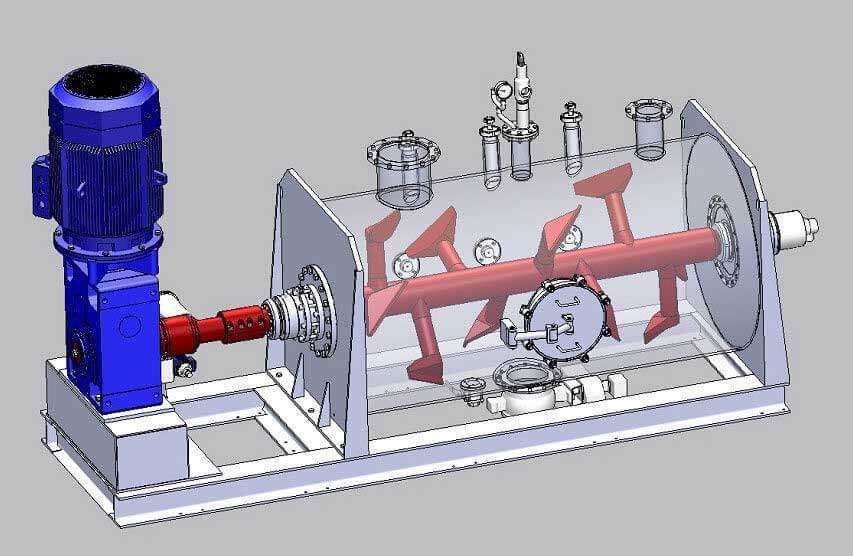

Vacuum Paddle Mixer Dryer

Application & Process :

The Vacuum Paddle Mixer Dryer is suitable for mixing and drying the material which can not operate at low Temperature easily oxidized, poisonous in nature. It operates at low Temperature efficiently. It is used for raw materials drying and mixing powder or granules of Pharmaceutical Materials, Crystalline, Insecticides, Pesticides, and Food industry and heat sensitive products.

- Material that cannot undertake high temperature.

- Material that is easy to oxidize.

- Material that do not permit to destruct.

- To recover material with residual volatile.

- Material with vigorous irritative and toxicity

The Vacuum Paddle Mixer Dryer consists of a jacketed cylindrical shell with rotating with specially designed Paddle Agitator type blade by rigid fabricated structure motor, gear box. There is provision for application of vacuumized inside the shell and circulation of heating media in the jacket during the rotation of the stirrer. The large heating surface area presented by the internals surface of the shell ensures uniform drying of the product, as the product gently moving & fluidized while the Paddle stirrer rotates. The diffusive action induced by the mixing stirrer constantly presents a fresh layer to come into contact with the indirectly heated walls of the shell. A well designed sealing system enable maintenance of deep vacuum inside the shell, and also ensures positive circulation of a heating media in the jacket.

In operation, material is filled to the top of the shell. The shaft rotates at relatively low speed and the moving paddles push and fluidized the material back and forth mixing it. The outer Paddle rotation displaces the material from the ends to the center while the inner paddle rotations move the material from the center to the ends. This counter-current action results in homogenous blending. Mixing is achieved in 15 to 20 minutes with 90 to 95 % or better homogeneity. The bottom discharge provided for unloading of the material and easy cleaning of the mixing drum. Specially designed self adjusting sealing arrangement of unique design is provided to ensure that no black particle enters into the mixing drum.

| Model | Total Capacity - Liter | Working Capacity- Liter | RPM | Motor Rating-HP |

| SB-5 | 8 | 3-5 | ||

| SB --25 | 40 | 20-25 | ||

| SB --50 | 75 | 25-50 | ||

| SB --100 | 150 | 70-100 | ||

| SB --200 | 300 | 150-200 | ||

| SB --300 | 450 | 225-300 | ||

| SB --500 | 800 | 400-500 | ||

| SB -750 | 1100 | 500-750 | Pl. Contact us for more details. | |

| SB -1000 | 1500 | 700-1000 | ||

| SB -1250 | 1900 | 950-1250 | ||

| SB -1500 | 2250 | 1100-1500 | ||

| SB --2000 | 3000 | 1500-2000 | ||

| SB -3000 | 4500 | 2250-3000 | ||

| SB -5000 | 7500 | 3750-5000 | 30 | 50 |

Salient Features :

- Design is cGMP- Current Good Manufacturing Practices compliance.

- All contact parts AISI 316 & non contact parts AISI 304.

- Continuous rotation of paddle stirrer, material will make continuous movement and fluidized in the container and reach to uniform mixing and drying at low temperature.

- Dust free operation.

- High vacuum operation

- Fast and uniform homogeneous mixing & draying at low temperature.

- Solvent recovery

- Continues vacuum maintain during process.

- Very low value of final moisture even at low drying temperatures.

- Option for two type design of shell 1. Cylindrical type and 2. "U" shape.

- Continues vacuum maintenance during process.

- Vacuumized closed system with condenser, Receiver for solvent recovery & Cyclone separator to recovery the solid particle.

- Rapid & Complete discharge / Zero holdup after discharge

- Heating media can be used steam/ hot water / hot oil.

- Rigid drive with reduction gear box, motor and stuffing box for shaft sealing.

- Charging pot, Vacuum connection, sight glasses, Vacuum relief valve & gauge are provided on top of the shell.

- Connection at jacket will be provided for steam Inlet, safety valve, Pressure gauge and steam trap.

- The discharge with butterfly valve/Slide valve at bottom side of the shell

Optional Features :

- Option for two type designed of shell 1. Cylindrical type and 2."U" shape.

- Option for Flame Proof Electrical.

- Option for Automatic Charging

- Option for lump breaker.

- Option for condenser, Receiver & Cyclone for solvent recovery.

- Option for advance PLC Controls with HMI touch screen.

Safety Features :

- Temperature controls, Vacuum relief Valve, Over load protection and Emergency stop.